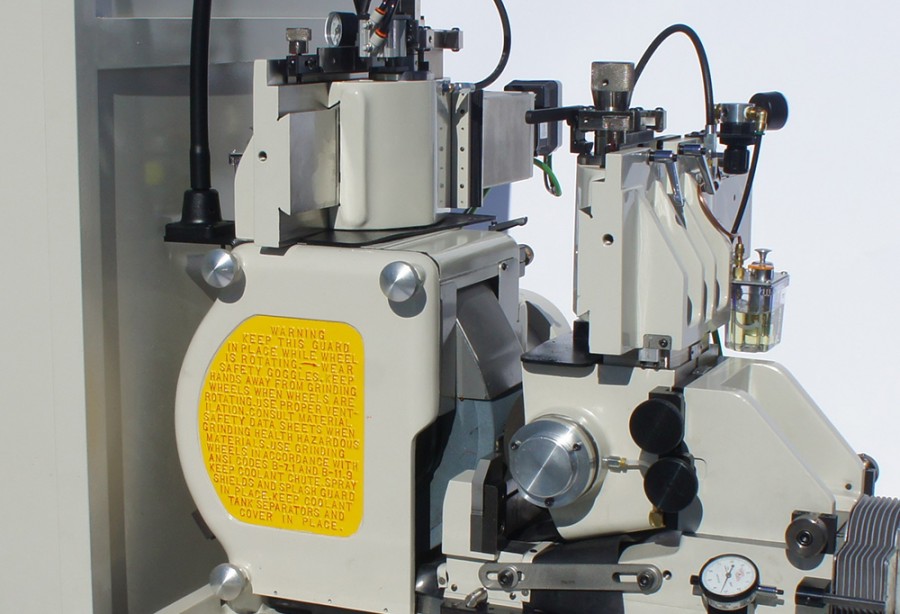

Manufacturing is a field where accuracy is a need, not only a standard. Ensuring that grinding wheels keep their shape and function during the milling process depends on Industrial wheel truing devices. These machines are used to fix wheel anomalies, remove uneven wear, and restore symmetry to guarantee the best grinding conditions. Tools and equipment would lose precision without regular truing, which would cause manufacturing delays and higher operating expenses.

Truing vs. Dressing: The Distinction

Though sometimes confused, truing and dressing have different roles in grinding wheel maintenance. While dressing exposes fresh abrasives and eliminates blocked debris, truing is the act of returning the wheel to its original geometric form. Here is when a wheel dressing machine manufacturer’s knowledge becomes really important. Engineered to exactly clean and condition grinding wheels, quality dressing machines improve their cutting performance and prolong their useable life. This combined emphasis on both truing and dressing guarantees that machines run smoothly and components are shaped to precise tolerances.

Industrial Wheel Truing Devices’ Contribution to Automation

Industrial wheel truing equipment has grown more sophisticated, fittingly merging with CNC systems and robotic arms as modern industries embrace automation. Without human involvement, these devices can now have constant truing cycles, real-time monitoring, and automatic changes. This increases uniformity across mass manufacturing lines as well as reduces downtime. Investing in consistent truing tools helps manufacturers see quick increases in throughput, lower scrap rates, and more confidence in the quality of the end product.

Selecting the Correct Wheel Dressing Machine Producer

Not all equipment is made equal; however, choosing a reliable wheel dressing machine manufacturer is very vital for any sector depending on grinding and machining operations. A good manufacturer gives innovation, lifetime, and precise engineering top priority. Their machines should have modern control systems for user-friendly operation, run with little maintenance, and accommodate several wheel kinds. Apart from the equipment itself, a good manufacturer offers training, technical assistance, and customization choices suited to particular manufacturing needs.

Improving Efficiency with Integrated Solutions

Manufacturers want instruments that do more than function in the competitive industrial scene of today; they need to simplify processes, cut waste, and lower human error. Often included with advanced industrial wheel truing equipment and dressing machines are integrated sensors, data analytics, and remote diagnostics. These intelligent capabilities let users track performance, monitor wear, and predict maintenance requirements before they become issues. Dealing with a forward-looking wheel dressing machine maker guarantees access to these technologies, so promoting a proactive rather than reactive attitude to production control.

Industries That Rely on Dressing and Truing Technology

A wide spectrum of sectors, from aerospace to automotive and from metal fabrication to medical device manufacture, rely on exact surface finishing and part shape. In applications needing micrometric tolerances and constant output over extended production cycles, industrial wheel truing equipment is particularly vital. In such high-demand environments, where every millisecond and micron matters, the value contributed by a consistent wheel dressing machine manufacturer is most clear. Choosing tools that provide consistent, high-performance outcomes becomes more crucial when production difficulties increase.

Wheel Maintenance Technology Future Trends

Looking forward, wheel truing and dressing will be automated, machine learning-driven, and sustainably designed. Already being developed by top manufacturers of wheel dressing machines are systems changing in real time to tool wear and workload changes. These developments provide notable decreases in manual supervision, reduced energy use, and higher output. Likewise, next-generation industrial wheel truing tools will probably be more compact, quicker, and smarter—bringing precise production to unprecedented degrees of complexity and accessibility.

Conclusion

Investing in superior industrial wheel truing equipment and dealing with an experienced wheel dressing machine manufacturer is a strategic choice for any business where precision, consistency, and productivity count. These instruments guarantee that equipment functions well and results satisfy demanding criteria, hence forming the foundation of efficient grinding processes. Manufacturers may cut downtime, increase equipment life, and keep market competitiveness by giving modern truing and dressing technologies a priority. Visit proemachinery.com to find out more about top solutions in this area.